Lever espresso machines have the lever attached to the group with steel pins and snap retaining rings. These rings require a special tool to remove. I have also seen different retaining rings that push on. Either kind is a pain to remove and I have scratched more than one lever handle removing them.

The solution, brass lever pins with a screw on the end to make easy removal.

We start with 360 brass rod 1/2″ diameter from online metals, I also picked some more up from 6061 Dude on ebay (great prices and shipping).

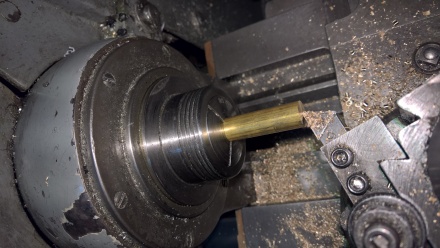

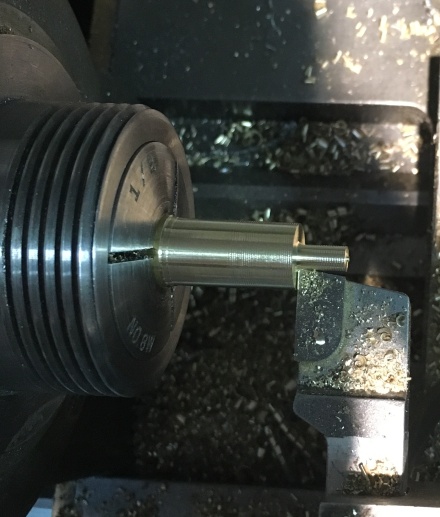

Next step is to clean up the rod. No rods are not perfectly cylindrical from the factory. Machinist and tool and die folk know this but this was new to me. I turned the outside down to 7/16 or so for the outside of the pin.

Next up, center drill. How I ever was able to drill without one of these?

Drill with a #29 for a 8/32 tap.

Early, when I first started making these I would tap at the end of all my cuts. Now I just do all the drilling and tapping before I turn down the pin.

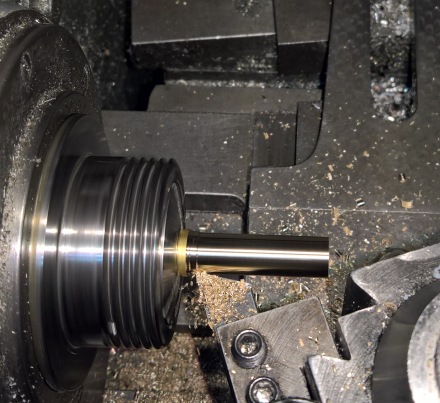

The pin diameter gets turned down to match the steel pins. The width is based on the machine. Cremina’s were 1.1″ wide, Pavoni’s varied from Gen 1’s .95 with the cast handles, to the gen 2’s with the pressed handle at .87-.9, La Cara .94, La Graziella .928, and Millenium Pavoni at .857. I had 12 machines to do so I custom sized each pair.

Once turned down to the right pin diameter I round the edges just a smidge with a file.

Now we are ready for to cut off the pin.

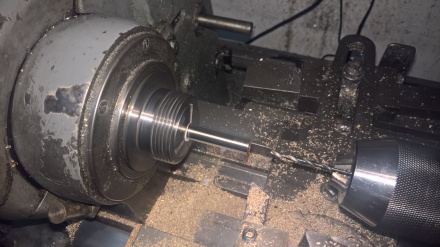

Then i re-insert the pin back into a smaller collet and finish the end to size and round over the corners like before. Sorry for the out of focus photo.

Now how do we make the other end. The same procedure is used for the end except we are turning down to a diameter to use a die for threads instead of for the pin.

Once turned, we use a die. A bit of oil and it takes but a moment to cut.

Next we clean up the inside and outside of threads to length.

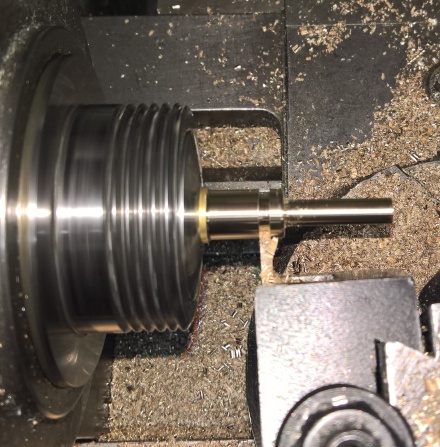

The cutting off is the same as the other. I re-inserted it into a collet and trimmed the end to size. On occasion I would tighten the collet a bit too tight and I’d have to run the threads through the die by hand to clean them up.

The old and the new.

Installed on a Cremina next to the old pin still in the back. Apparently I need to clean my machine more as everything shows up in the photos!

Installed on a Cremina next to the old pin still in the back. Apparently I need to clean my machine more as everything shows up in the photos!

What did we learn here:

- I get a lot faster with each set.

- A CNC lathe would make this much faster and automated or a screw machine. I don’t need that many and I do not have access yet to a CNC lathe which would make them profitable to sell.

- Maintenance now is so much easier. No longer do I have to search for snap ring pliers or worry about scratching the lever. I just unscrew with my fingers and remove the pins. They stay together quite well and on occasion I tighten them if things loosen up.

Other solutions I have seen people do is thread brass rod with acorn nuts. I didn’t like the aesthetics of the acorn nuts so I went this route.

Brass wears before the steel lever, piston rod or the group head and was selected for this reason. These are expected to wear and are easier to replace than a rounded out group head or piston rod. I use some pin lube from Orphan Espresso on installation.

Another upgrade is using bearings with the back pin instead of the roller. I did get some from ebay , MR126ZZ 6 X 12 X 4 Bearing, from the seller rc-bearing .Shims from McMaster Carr, part number 98055A106, Spring Steel Round Shim, 0.2mm Thick, 6mm ID, 12mm OD. I put three bearings with shims between and on the outside. This replaces the back roller. For more info on this check out home-barista.com and search on lever pins. This upgrade was from the contributor DrGary.

Mike its time to get a job.

Can I purchase one of these from you?

You have likely found them on ebay from someone who sells them in one size only. Another is in germany I think. You can send me a pm, if I have shop access, I make them for 25 plus shipping. I need to know the year and handle style, preferably a measurement with some calipers.

Hello Mike, I have a 1974 and a 1979 Europiccola, The ’74 I think is missing the shower screen and needs gaskets. The 1979 needs the hi power boiler tested or baked because it causes a GFCI trip could I pay you to make these repairs?

I cannot do any repairs at this time. The 79 i would get a new element if its not working from Stefano”s espresso care, its a three screw, he can help you with all you need for it. The 74, he has gaskets and the shower screen is available as it fits over the brass sleeve.